Our Cable Protection Systems

First Subsea have worked closely with clients on over 70 cable protection system projects, suppling many thousands of system to offshore wind projects across the world. With an ever expanding track record, First Subsea has a wealth of knowledge and experience, with expertise in CPS design, analysis, project management, manufacturing, testing and installation.

First Subsea’s Cable Protection System (CPS), is ideally suited for use in a range of offshore wind applications, including monopile and J-tube installations, protecting array, export, interconnector and fibre optic cables, and for projects where scour development and scour protection are present. From initial engagement through to installation, First Subsea have a wealth of experience to support project demands to ensure smooth and efficient project execution.

Key Features:

Vast experience across a broad range of products

Significant manufacturing capacity to de-risk project execution

Proven installation and disconnection of systems

Expertise in CPS design, analysis and engineering

CPS solutions designed with fatigue, abrasion and impact in mind

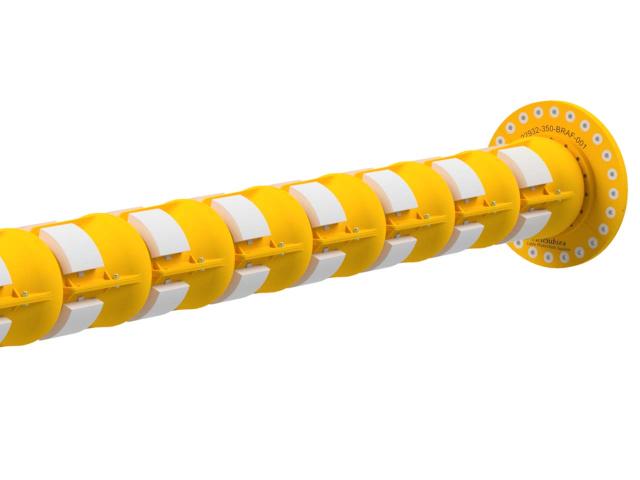

First Subsea’s Proshell is a Polyurethane split pipe cable protection system designed to protect the cable from impact and abrasion. Typically used to protect static and dynamic cables positioned near the seabed, First Subsea’s Proshell system comprises of two identical interlocking half-shell mouldings that are configured to closely match the diameter of the cable to be protected.

Key Features:

Excellent impact and abrasion protection

Proven floating wind track record

Offered in 1.5m lengths for ease of handling

Profiled design, ensuring it will not separate during installation

Quick and easy installation

First Subsea’s Bend Restrictor is a metallic split pipe cable protection system designed to protect the cable from impact and abrasion. Commonly utilised on cable repair joints and beach landings, First Subsea’s bend restrictor system comprises of two identical interlocking half-shell mouldings that protect cables positioned near or on the seabed.

Key Features:

Excellent impact and abrasion protection

Prevents the cable overbending and breaching MBR

Proven CPS track record

Quick and easy installation

Can be provided with a range of corrosion protection methodologies

Via our collaboration with Kintech Energy Ltd, First Subsea can offer a Resin Free Hang-off (RFHO) featuring a unique design incorporating flanges and gaskets in combination with an upper sealing system to provide a pressure resistant seal for air tight platforms. The configuration of the RFHO can be designed to fit a range of interfacing flange sizes in monopile structures, jacket foundations, substation j-tubes and floating wind structures.

Key Features:

Minimises cable termination and disconnection times

Resin free design so reduced HSE concerns

Suitable for installation on a range of interfacing flange sizes and cable design combinations

Hang-off's can be easily removed and re-used

Removes any reliance on using marine grade resins to maintain an air tight seal